In today’s fast-paced business environment, it’s essential for companies to have a streamlined inventory planning process in place. Unfortunately, many businesses still rely on manual methods which can be time-consuming and often result in stockouts or overstocking. Recently, one of our clients reached out to us with this exact issue. They were struggling to keep up with demand and maintain optimal inventory levels. We introduced them to NetSuite’s demand planning module and they’ve been nothing short of thrilled with the results. In this blog post, we’ll explore what demand planning is, how it works in NetSuite, and why it’s so important for your business.

Demand Planning is a supply chain management process that helps businesses forecast future demand for goods and services. It puts an operational plan in place to adjust output and balance inventory levels with consumer demand, avoiding overproduction. Demand Planning is essential for optimizing inventory levels, increasing turnover, and reducing costs, as it offers complete visibility into day-to-day operations.

NetSuite’s Demand Planning Module makes it easy to manage the inventory process. The following flowchart illustrates the Demand Planning process:

Configuring Demand Planning

To configure Demand Planning, follow these steps:

- Enable Features: Go to “Setup” > “Company” > “Enable Features” page. Under “Items and Inventory”, make sure to check the box for “Demand Planning”.

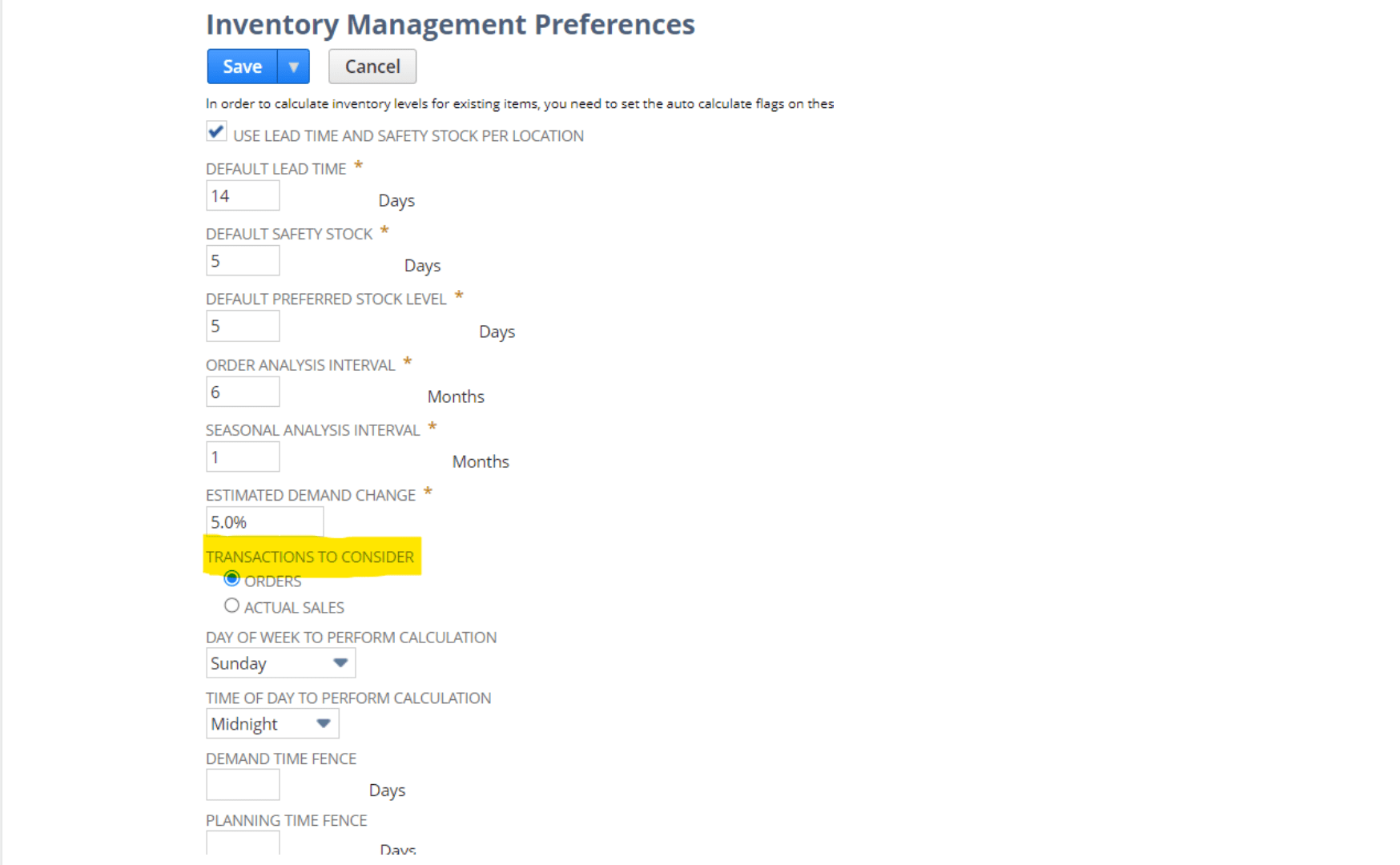

- Inventory management Preference: Go to “Setup” > “Accounting” > “Inventory Management Preference” page. Under the “Orders to Consider” options, select either “Sales Orders” or “Invoices”, depending on which orders you want to consider for Demand Planning calculations.

- Location Setup: Make sure to mark the “Include in Supply Plan” checkbox for the locations you want to include in the planning.

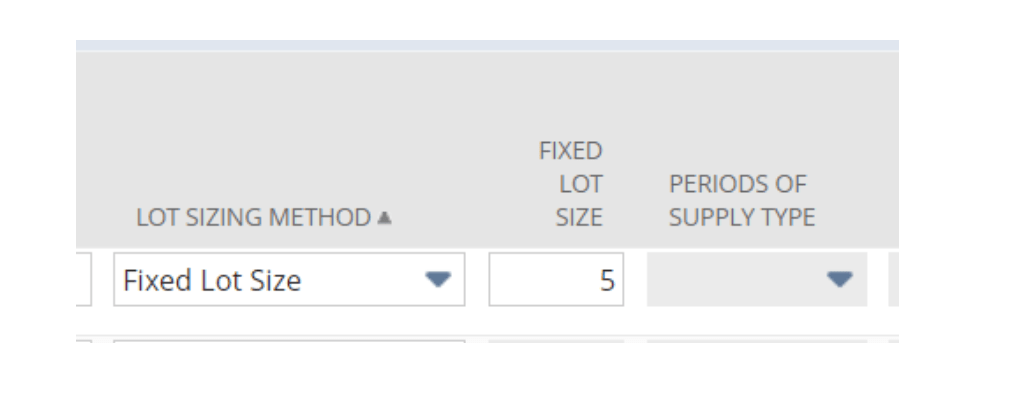

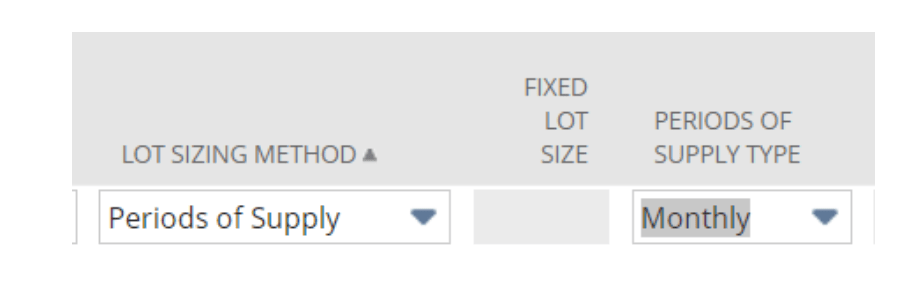

- Item Setup: Make sure the items have a “Replenishment Method” of “Time Phased”. You can also specify a “Lot Sizing Method” for the location where you want to run the Demand Planning. There are 3 types of Lot Sizing Methods:

- Lot for Lot: Suggests orders for procurement based on daily projections.

- Fixed Size Lot: Suggests orders for procurement based on a fixed amount or a multiple of the fixed amount.

- Period of Supply: Generates aggregated purchase orders or work orders based on overall demand requirements over a designated period.

- Demand Source: At the Item level, specify a “Demand Source”. There are 4 options available:

- Entered and Planned Orders: The supply plan will be generated based on previous orders and will not take into consideration orders suggested by Demand Planning.

- Forecast from Demand Plan: The opposite of the previous option, this plan will take into consideration only demand plan orders and ignore historical orders.

- Forecast and Orders: This option will take into consideration demand plan orders as well as historical orders, resulting in the most suitable supply plan.

- Forecast Consumption: Similar to the previous option, but with the added option to include forward and backward consumption dates, beyond the specified date range, to generate a plan.

Running Demand Planning

Once your Demand Planning configuration is complete, you can run the plan by going to “Transactions” > “Demand Planning”. From there, you can select your desired date range, locations, and items to generate a demand plan. There are 4 options to generate the projections for demand:

- Linear Regression – Use previous demand to project future inventory needs assuming a steady linear growth.

- Moving Average – Use previous demand to calculate the overall average stock level needed, and then project future stock levels using that overall average.

- Seasonal Average – Use previous demand to examine the seasonal trend of inventory flow, and then project a similar seasonal trend for future stock levels. Note: Using this method, the projection interval must be set to Monthly intervals.

- Sales Forecast – When using NetSuite for your sales operations, this option uses forward-looking sales forecast data to project inventory demand. When you use the Sales Forecast method, transaction types sourced for projection calculations are cash sale, invoice, estimate, opportunity, sales order, and item fulfillment.

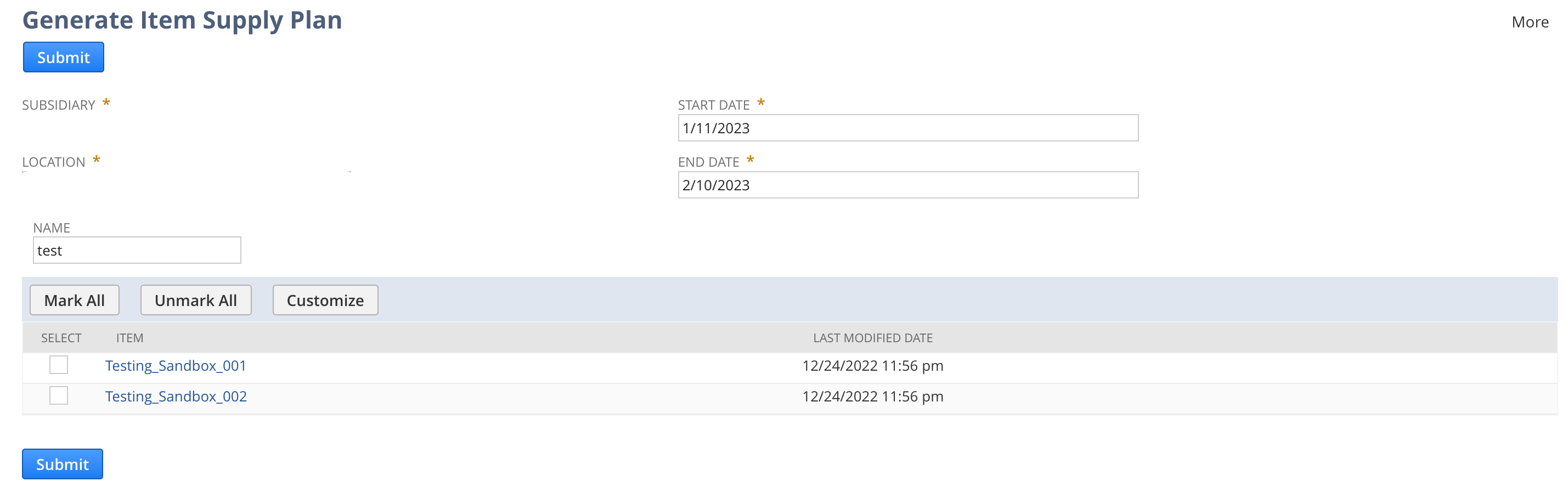

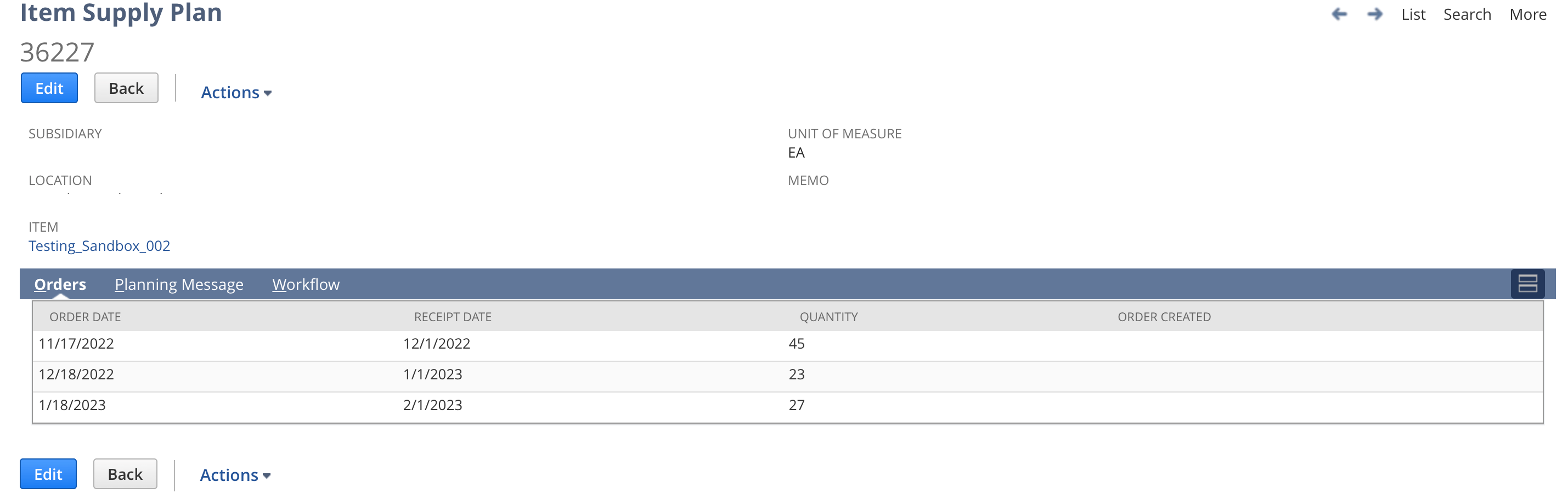

The final step is to generate the Item supply plan. Navigate to Transactions > Demand Planning > Generate Item Supply Plan.

In conclusion, Demand Planning is a crucial process that helps businesses optimize inventory levels and reduce costs by forecasting consumer demand. With the help of tools like the NetSuite Demand Planning Module, it’s possible to effectively manage the inventory process and keep your business running smoothly.

Reach out to us to get assisted by our talented team.

Let's Discuss Your Requirements.

Ready to take your business to the next level with NetSuite? Contact Consule Solutions today and let our experienced team guide you through the process. Start optimizing your business processes and driving growth with Consule Solution and NetSuite.